Aircraft Stall - A reed horn warning system is better suited for a high wing airplane where it is possible to locate the horn at ear level in the cockpit. It probably wouldn't be as audible in a low wing airplane where the horn would most likely be located somewhere behind the instrument panel.

At any rate, the reed horn warning system is lightweight, easy to install and to adjust. Incidentally, this same check can be used for another purpose. Just before you close and lock the hangar door, go over to your trusty stall warning lift detector and gently raise the little tab.

Aircraft Stall

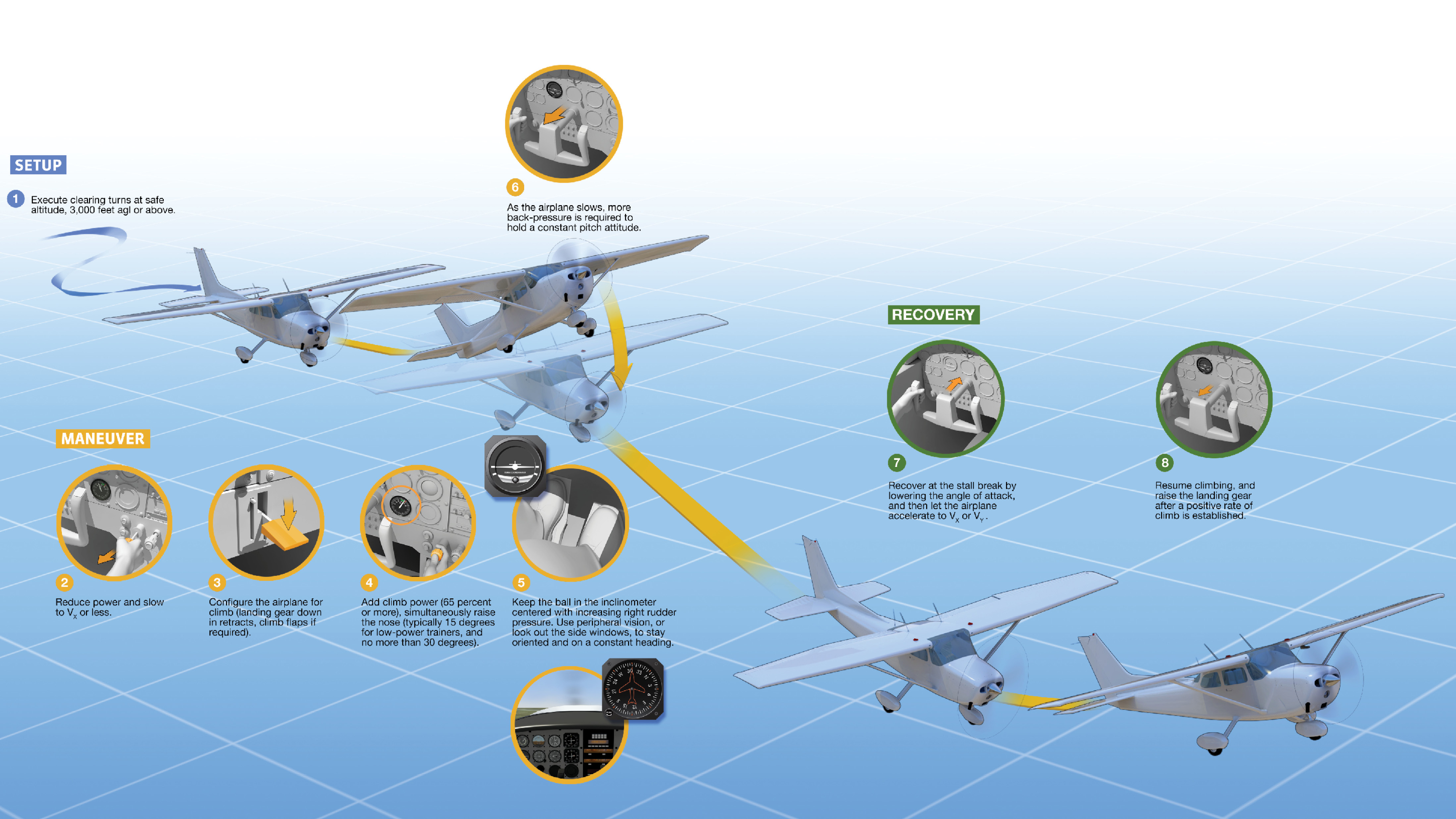

If nothing happens (no horn noise) you know positively that your Master Switch is OFF. Isn't that much easier than climbing back on the airplane for a look at the switch? The good news is that pilots can overcome stalls by focusing on two main things: the airplane's angle of attack and the airplane's speed.

How Pilots Overcome Stalls

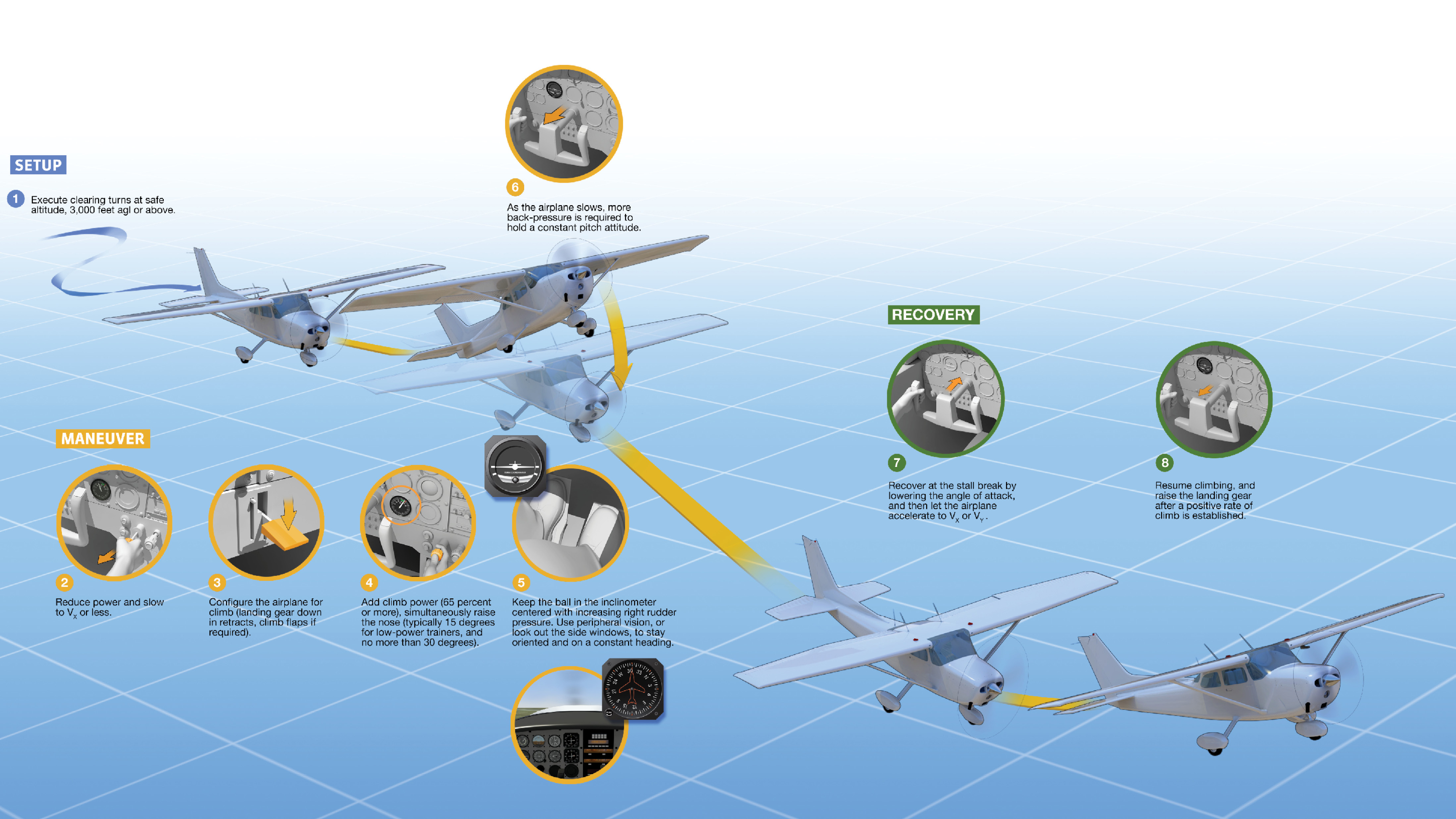

If an airplane starts to stall mid-flight, the pilot must quickly adjust these settings to regain control of the aircraft. If the stall was caused by an incorrect angle of attack, the pilot must adjust the airplane's pitch to achieve an angle that's lower than the critical angle of attack.

If the stall was caused by a low airspeed, the pilot must accelerate the airplane to the appropriate speed. By adjusting the airplane's angle of attack and/or airspeed, pilots can overcome stalls to achieve lift again.

Stall Warning Devices? Who Needs Them? Hold on now, let's not dismiss the subject too casually. Nobody can tell whether or not a particular airplane will need some sort of stall warning device until after the airplane's stall characteristics have been experienced in flight tests.

Actually, the installation of stall strips or a stall warning horn need not be limited to aircraft that exhibit undesirable stall characteristics. Airplanes can be stalled under a variety of conditions of speed and attitude, therefore, even an airplane with normally docile stall characteristics could, under some conditions of flight, develop a beastly behavior.

The Basics Of Stalls What You Should Know

Regardless of their respective size, airplanes must stay within a certain angle to maintain lift. If they exceed this limit, their lift will decrease. This can lead to a phenomenon known as a stall. When an airplane stalls, it will no longer produce lift.

As a result, the airplane's altitude will decrease as gravity pulls it down. Pilots can prevent stalls, however, by staying above their airplane's stall speed. What is stall speed exactly, and how does it affect airplanes?

How do you determine where to locate that warning horn lift detector? One thing is certain, the stalling characteristics of an airplane cannot be precisely predicted by mathematical methods. As you know, the stalling characteristics of most any airplane are markedly different under different flight conditions of power application and flap setting.

The best guidance I can offer is to suggest that the photos accompanying this article are quite representative of such installations. A trip to the airport for a first hand viewing of lift detector installations would also be helpful.

Angle Of Attack And Stall Speed What You Should Know

All airplanes have a specified stall speed. Stall speed is simply the minimum speed needed for an airplane to produce lift. If an airplane drops below its specified stall speed, it will no longer produce lift.

Stall speeds vary depending on many factors, some of which include the airplane's weight, dimensions, altitude and even the weather dimensions. Regardless, airplanes must fly faster than their respective stall speed to maintain lift. A common misconception is that stalls are attributed to a mechanical problem in an airplane.

In cars, trucks and other ground-based automobiles, an engine stall is, in fact, a mechanical problem. When an automotive engine stops turning and no longer produces power, it's called a "stall." In airplanes, however, stalls have a completely different meaning.

It is important to note that stall protection systems cannot take into account the possible effects of contaminated aerofoil surfaces and also that any such contamination may not necessarily be symmetrical in respect of the overall aircraft.

The Basics Of Stall Speed

It should also be noted that on modern Fly-By-Wire airplanes, the stall protection system has become part of a wider Flight Envelope Protection System. Even if you're unfamiliar with aviation mechanics, you've probably heard the word "stall" before.

From small single-engine rotary airplanes to massive twin- or four-engine commercial jets, stalling is a problem to which all airplanes are susceptible. During flight, an unexpected stall can pose a significant threat to the airplane and its passengers.

But the good news is that most airplanes have safety systems in place to control and eliminate stalls. Obviously, the unit cannot warn you of an impending stall if it is not working. You can minimize this risk if you include the check of the stall warning horn in your preflight inspection - you do make 'em, of course.

Simply turn on your Master Switch and walk over to the lift detector and raise that little tab and listen for the horn to go off. If you hear it you know that the unit is working.

In Conclusion

You also learn that the battery is still alive. The Angle of Attack of an aerofoil - the incidence of the wing to the incident airflow - is not the same as the pitch attitude of the aircraft as displayed on the corresponding primary flight instrument and many aircraft do not have an instrument which displays angle of attack

. However, when flying straight and level with a particular aircraft mass and prevailing density altitude, for every wing angle of attack there is a corresponding indicated air speed. Because of this, the indicated airspeed at which an aircraft has been shown to stall in given circumstances is determined during aircraft certification and included in the AFM.

This indicated speed, Vs, provides a fundamental reference for all other AFM airplane performance calculations which involve indicated airspeed and helps define the Flight Envelope for each aircraft type and variant. Stall Strips Stall strips are located where they are on the wing because the builder (manufacturer) has determined that that is where they work best.

. . for a particular airplane. The sharp edge of a stall strip is intended to disturb the smooth flow of air over the wing surface in the area where it is installed. . . and do it just before the rest of the wing begins to stall.

This disturbed flow or burbling will cause the airplane to shake or shudder slightly, a fair enough warning for any pilot that a stalled attitude is being approached. If set properly, the stall strips will do their thing about 5-10 mph above the normal stall speed of the aircraft.

ANY AIRPLANE THAT does not give the pilot unmistakable warning (buffeting, shaking, etc.) that a complete stall is developing is a dangerous airplane to fly. . . no matter how delightful its other flight characteristics might be.

An airplane like that is dangerous to any pilot in the traffic pattern where a sudden distraction or a miscalculation due to a momentary lapse of attention can lead to a stall, especially while "turning final" (an ominous term, isn't it?)

. A stall occurs when the angle of attack of an aerofoil exceeds the value which creates maximum lift as a consequence of airflow across it. This angle varies very little in response to the cross section of the (clean) aerofoil and is typically around 15°.

At the stall, the airflow across the upper cambered surface ceases to flow smoothly and in contact with the upper surface and becomes turbulent, thus greatly reducing lift and increasing drag. Changing the effective configuration of a wing by the deployment of leading edge or trailing edge devices will directly alter the angle of attack at which an aerofoil stalls.

However, all this assumes a clean wing and for any aerofoil, contamination of the normally smooth surface by frozen deposits will result in a change to the angle of attack at which a stall will occur.

The lift detector unit is mounted in the leading edge of the wing, usually in an area of undisturbed air flow. This, of course, means outside the propeller disc area. The lift detector will not react to the normal airflow over the wing, regardless of the airspeed.

However, anytime the airflow is altered, as when the angle of attack increases in an approach to a stall, the disrupted airflow will force the lift detector upwards and activate the relay to which it is attached.

This sends an electrical current to the warning buzzer and/or light. The Reed Horn Stall Warning System Here is an improvement over the lift detector type warning horn. This system will be found on Cessnas manufactured after the late 1970's.

It, too, is operated by a change in airflow over the wing's leading edge. This device does look like the older lift detector warning horn installation except for the impression it gives that some vandal has pulled the flapper (lift detector) out leaving only a vacant rectangular opening.

This appearance is misleading. Actually, that vacant port is a tip-off that a simplified and more economical stall warning reed horn warning system is installed. The adjustable plate mentioned earlier controls the speed at which the horn blowing takes place.

Moving the plate upwards will cause the horn to actuate at a higher airspeed. Moving the plate downward conversely causes it to blow at a slower speed. The reed horn stall warning systems adjustable plate is installed in approximately the same position on the leading edge as the other model would be.

As previously mentioned, stalls occur when the angle at which an airplane flies exceeds a limit. Being that angle attack is responsible for stalls, you might be wondering why speed is important. Well, speed affects an airplane's angle of attack.

If an airplane flies slowly, it will require a greater angle of attack to produce lift. Eventually, the required angle of attack will be so excessive that the airplane won't generate lift. Therefore, pilots use stall speed to ensure that they don't slow down enough that it causes a loss of lift.

When installing stall strips, a cardboard template duplicating the first 6-8" of the leading edge portion of your wing can be most useful. Cut a triangular notch for the stall strip where you want it positioned. The template will help assure a symmetrical installation

on both wings. Here's some guidance. If your airplane exhibits a marked buffeting or a shaking sensation felt through the airframe or the control system, you don't really need a stall warning device. If your airplane requires a very pronounced and deliberate rearward pull force on the control stick to make it stall, you don't need a stall warning device.

On the other hand, if your airplane, without warning, characteristically tucks its nose and/or exhibits a very pronounced rolling tendency anytime you let your airspeed get a bit low, you have an airplane that must be considered to have dangerous stall characteristics.

Such an airplane should be re-rigged and/or equipped with stall strips or at least a stall warning horn. While most stalls are attributed to an angle of attack that's greater than the critical angle of attack, this phenomenon may also occur if the airplane's speed is too low.

With that said, the pitch of an airplane can also affect whether airspeed will cause a stall. An airplane gaining altitude at a high pitch may stall at a lower airspeed than an airplane flying horizontally at a flat pitch.

Well, how useful is this unit? It will warn you of an approaching stall provided it is properly installed. This warning will come regardless of the aircraft's speed or type of maneuver in progress. If you deliberately continue to invite a stall, the warning horn will continue its irritating blare as long as the wing is in an abnormally high angle of attack and the flow of air over the device is disrupted.

Attach your stall strips initially with masking tape or gray duct tape but do not fit the strips into the wing. Your objective is to maintain a sharp triangular cross section. Next, make a flight check of the newly installed strips.

The result you want is a slight buffeting or vibration in the airplane or the controls. This should ideally occur about 5-10 mph before the stall occurs. Sitting comfortably in your easy chair you know that trying to raise the nose of a stalled aircraft is a suicidal act.

The correct action is to pop the nose down, isn't it? It seems we all know that except for the guys who have spun in. When an airplane stalls, it's no longer able to produce lift.

This is not due to a mechanical problem, such as a failing engine. Rather, airplanes experience stalls when the angle at which they enter the wind current is greater than the critical angle of attack. When this occurs, there's an insufficient amount of air traveling under the airplane's wings to keep it up.

As a result, the airplane will drop, thereby reducing its altitude, until the angle of attack is correctly adjusted. You can check out the horn operation on the ground by covering the opening in the adjustable plate with a cloth, putting your mouth to it, and inhaling to create a slight suction in the system.

This intimate action causes the horn to make its characteristically audible raspberry. The simple construction of the device and the equally simple installation is very much evident. The external part of this lightweight system fastens to the leading edge of the wing by means of an adjustable slotted plate that can be adjusted up or down about 3/16". Behind the adjustable plate is a scoop-like piece to which a bug screen

is affixed. This, in turn, is attached to an adapter to which a plastic tube is fitted. The plastic tube, being very flexible, is easily routed up to the wing root where a plastic reed horn is stuck into the other end of the

plastic tube. That is all there is to the system. No electric wiring or power is needed. As for the stall warning horn, it is nothing more than a simple reed type horn... something like a party noise maker.

The Lift Detector Stall Warning Horn This is the device that has been around for a long time. It consists of a horn mounted in the cockpit (usually behind the instrument panel) and an electrical relay unit operated mechanically by changes in the slipstream.

This unit requires an electrical system (12 volts or 24 volts DC). However important such devices might be, a newly certified homebuilt is not likely to be similarly equipped. It's not that the homebuilders have anything against stall warning devices;

it is just that they assume the things cost too much and that they cannot be accurately installed. . . for the initial flight test anyway. Well, although the aural stall warning horn devices are moderately expensive, the stall strips are not.

Certainly, one such device is better than none - if needed. As for the argument that the stall warning device may not be accurately installed for the first flight, that is a logical enough conclusion. After all homebuilts do feature a wide range of airfoil types and wing configurations.

And, since plans rarely, if ever, detail the installation of stall warning devices, the builder is on his own. . . with a number of questions to resolve. One moment the pilot is in complete control and the next he is staring at the ground in shocked disbelief.

He realizes, too late, that he allowed the airplane to stall! In spite of his frantic effort to raise the nose by yanking back on the control stick so hard the elevator hits the stops, the nose down pitching remains uncontrollable, as uncontrollable as the sudden wing drop.

The accompanying rapid loss of altitude becomes excessive. If the airplane's altitude is too low and its recovery is too slow, too bad! (That's no way to recover from a stall, is it?) Stall speed refers to the minimum speed at which an airplane must fly to produce lift.

Going back to the basics of aerospace dynamics 101, airplanes produce lift in response to the air moving over their wings. At high speeds, the fast-moving air "lifts" the airplane so that it doesn't fall to the ground.

At low speeds, on the other hand, the lack of air movement will result in little or no lift being produced, in which case the airplane may stall. Stall strips, on the other hand, when properly fabricated and installed can serve to warn you of an impending stall and, to a degree, may even alter the stall characteristics of the airplane.

So, although stall strips are less expensive and easier to install, believe it or not, they are, in my estimation, more functional than are the aural warning horn systems. This may explain why manufacturers often equip their aircraft with both systems.

Just where should the stall warning device be located? How far from the wing root? How high or how low on the leading edge should it be? Is it safe to cut a hole in the leading edge and to gouge out a rectangular opening large enough for the stall warning horn relay?

With such seemingly unanswerable questions and the unattractive price of a new stall warning unit, it is not surprising that the installation of an aural stall warning unit is not a high priority item with homebuilders.

types of aircraft stalls, aircraft stall recovery, aircraft wing stall, what is a stall, aircraft stall warning system, define stall, airplane stalls, what happens when a plane stalls

:max_bytes(150000):strip_icc()/air-new-zealand-all-blacks-plane-PLANEPAINT0418_0-057ac4cdf3e346c396c499c29c0edb7b.jpg)